Machine Tool Scraping Services

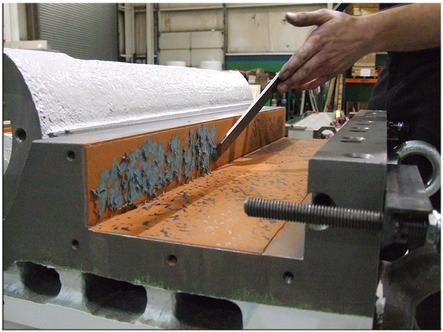

Hand scraping is a manual process that requires an individual to use a hand tool called a flat scraper to scrape metal from a machine tool surface in order to create contact points and oil grooves on surfaces that need to be mated together. By removing very thin layers of metals from a precision surface, you eliminate the high points created by the machining process and provide a true degree of flatness allowing two surfaces to smoothly glide across each other.

Machines that require scraping are those that contain boxed or cast-iron ways. We have worked on a wide variety of makes and models. Some of the most popular machines that require scraping are G&L Boring Mills, Makino Machining Centers, Okuma Machining Centers, OKK Machining Centers, Cincinnati Gilbert Boring Mills.

What are the benefits of machine tool scraping?

- Hand scraping ensures tight tolerances, the only method for producing true flatness, and the creation of oil pockets allow the surfaces to glide across each other instead of sticking.

- The level of accuracy and flatness that can be achieved by removing the imperfections in the surface will greatly improve the geometry of the machine.

- A machine with hand scraped key components will provide consistent results over a longer period of time and extend the life of your machine. KRC understands the importance of hand scraping and how it extends the life of your machine which is why we only use highly skilled and experienced hand scrapers who almost exclusively do hand scraping. Our scrapers can scrape all the mated surfaces on your machine.

How often should you preform Machine Tool Scraping?

Normal wear and tear of production can cause a decrease in accuracy and performance. A noticeable decrease in accuracy or signs of wear on your machine means it is probably time to have it disassembled and rescraped to restore it to OEM Specification.

Contact Us

Many clients rely upon KRC Machine Tool Solutions because we overcome difficult challenges with sound, simple results. We’ll meet your timeline and surpass your objectives. Contact us for more information about our specialty machine solutions.