Velocity VTC Series

The Velocity VTC Series offers the latest in vertical turning precision and performance.

- Exceptional Performance – The Velocity Series is a full line of Vertical Turning Lathes (VTL’s) that are crafted to deliver exceptional performance and surface finishes on large workpieces. These powerful, high precision, vertical turning lathes are available with swing diameters from 1200mm to 2000mm.

- Superior Rigidity and Stability – The main structure of the machine is comprised of heavy-duty castings for superior rigidity and stability. Each casting is designed to limit thermal distortion and absorb any resonate vibrations created during machining.

- Adjustrable Crossrail Features – The adjustable crossrail features a 15º slanted box way design and is a programmable positioning axis; able to handle a wide range of parts and minimize ram extension.

- Withstand Heavy Forces – The hydrostatic Z axis is a large cast steel ram that maintains rigidity even when fully extended. It is designed to withstand the forces of heavy inner and outer diameter cutting while assuring dimensional accuracy on both sides.

- Customizable – All models can be custom configured with live milling (C Axis), custom tooling or optional accessories to best fit most any application or process requirement. Machines can be supplied with either a Fanuc or Siemens control system.

KEY FEATURES

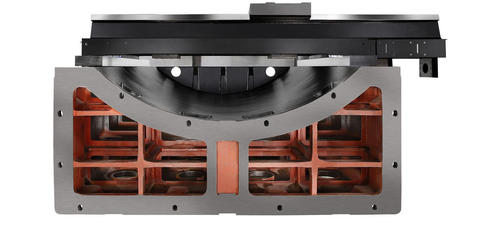

HIGHLY RIGID AND DURABLE FRAME STRUCTURE

The one piece bed and box type column castings are designed for rigidity and stability; even under the heaviest of cutting conditions. Fine grained Meehanite cast iron is used for its excellent strength, wear resistance and vibration dampening characteristics.

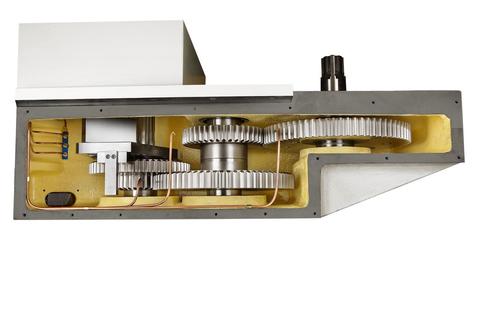

TABLE DRIVE SYSTEM

The table drive system is designed to provide ample cutting power for a wide variety of materials. Powered by large spindle motors, our high precision 2-speed gearboxes deliver massive torque values (up to 23,270 N-m of maximum torque) for heavy duty machining, even at low table speeds.

HEAVY DUTY TABLE

A thrust cylindrical roller bearing with a heavy duty taper roller bearing is used to achieve high axial and radial loads while yielding longer service life and higher accuracy. These bearings sit in a rigid one piece base casting, providing the ideal combination of increased table load and machining precision.

| U/M | VTC-12 | VTC-16 | VTC-20 | ||

|---|---|---|---|---|---|

| Capacity | Table Diameter | mm (inch) | 1,250 (49.2) | 1,600 (63) | 2,000 (78.7) |

| Max. Turning Diameter | mm (inch) | 1,500 (59.1) | 1,900 (74.8) | 2,400 (94.5) | |

| Max. Swing Diameter | mm (inch) | 1,600 (63) | 2,000 (78.7) | 2,500 (98.4) | |

| Max. Turning Height | mm (inch) | 1,250 (49.2) | 1,600 (63) | 1,600 (63) | |

| Max. Table Load | kg (lb) | 6,000 (13,228) | 10,000 (22,046) | 13,000 (28,660) | |

| Table/Spindle | Table Speed | rpm | 1 - 300 | 1 - 250 | 1 - 200 |

| Max. Torque of Table | N-m (lb-ft) | 10,655 (7,859) | 18,790 (13,859) | 23,270 (17,163) | |

| Max Cutting Force | N (lb) | 25,000 (5,620) | 25,000 (5,620) | 25,000 (5,620) | |

| Table Main Motor | kW (HP) | 37/30 (50/40) | 45/37 (60/50) | 45/37 (60/50) | |

| Travel/Rapid Traverse | Cross Travel X axis | mm (inch) | -200(-7.87) to 950 (37.4) | -250(-9.84) to 1,125(44.29) | -250(-9.84) to 1,380(54.33) |

| Vertical Travel of Ram Z axis | mm (inch) | 900 (35.4) | 1,000 (39.4) | 1,000 (39.4) | |

| Vertical Travel of Crossrail W Axis | mm (inch) | 800 (31.5) | 800 (31.5) | 800 (31.5) | |

| Rapids on X Axis | MPM(IPM) | 12 (472) | 12 (472) | 12 (472) | |

| Rapids on Z Axis | MPM(IPM) | 10 (393) | 10 (393) | 10 (393) | |

| Machine Dimension | Length | mm (inch) | 5,900 (232.3) | 6,500 (181.1) | 7,800 (200.8) |

| Width | mm (inch) | 3,800 (149.6) | 4,600 (181.1) | 5,100 (200.8) | |

| Height | mm (inch) | 5,020 (197.6) | 5,690 (224) | 5,740 (226) | |

| Weight | kg (lb) | 20,000 (44,092) | 28,000 (61,729) | 42,000 (92,594) |

All three of the above models (VTC-12, VTC-16, and VTC-20) are offered with a Live Spindle option. The Live Spindle option is denoted by adding a “C” after the model number (Ex. VTC-16C). The following specifications apply to the Live Spindle designation

| Description | Velocity Turning Lathes | Unit | VTC-12C | VTC-16C | VTC-16C |

|---|---|---|---|---|---|

| Live Spindle w/ C-Axis | Spindle speed | rpm | 24 - 2,400 | 50 - 2,250 | 50 - 2,250 |

| Max. Torque of Spindle | N-m (lb-ft) | 196 (145) | 196 (145) | 196 (145) | |

| Spindle Motor | kW (HP) | 7.5 (10) | 11 (15) | 11 (15) |

| Standard Accessories | |||

|---|---|---|---|

| Fanuc System 0i-TF or Siemens 828 CNC Controller | High Pressure Pump (3 Bar) | Heat Exchanger for Electrical Cabinet | Signal Tower Light |

| 12 Tool ATC | Table Lubricant Oil Cooling Unit | Table Manual 4-Jaw Chuck | Anchor Bolt & Tools and Tool Box |

| (BT 50 or CAT 50) | |||

| Chip Conveyor & Coolant Tank | Machine Cover (Semi-Opened) | Hydraulic Unit | Operation Manual & Spare Part List |

| Oil/Water Separator | Auto Lubrication System | Work Light | Metal frame and case in machine shipment packing |

| Optional Accessories | |||

|---|---|---|---|

| C-Axis w/ Live Milling | 18 Tool ATC w/ Live Milling option | Through Tool Coolant | Tool Probe (Renishaw or Blum) |

| Auto Tool Changer w/ CAT Holders | Additional Tool Holders | High Pressure Pump (6 Bar, 10 Bar, or 20 Bar) | Part Probe (Renishaw or Blum) |

| Automatic Hydraulic 3 Jaw Chuck | Transformer for Power Source | Pallet Shuttle or Part Handling System | Linear Scales on X, Z axis (incremental or absolute) |

Contact Us

Many clients rely upon KRC Machine Tool Solutions because we overcome difficult challenges with sound, simple results. We’ll meet your timeline and surpass your objectives. Contact us for more information about our specialty machine solutions.